Ramox

High quality snow ploughs for Unimog and trucks

Available in the lengths from 2,600 mm up to 3,600 mm

Snow ploughs from the series Ramox are high quality snow ploughs for professional use in the local area. The more-furrow ploughs with single-sided hoisted plough share have a stable ladder frame. All Ramox ploughs are equipped with automatic plough share retrieval. Through this automatic protection of each plough share, they are held reliably in the clearing position, also in hard snow removal action, but swerve elastic solid obstacles, yet.

Get to know the Ramox snow ploughs

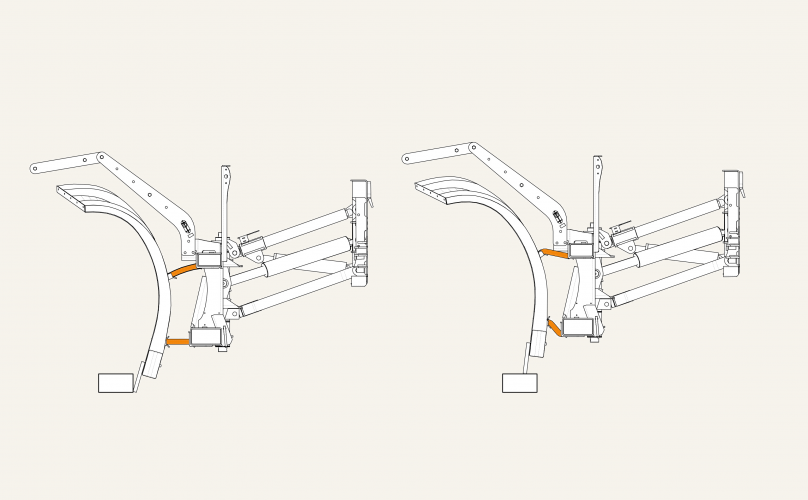

The safety system of the snow plough is based on the elastic connection between the segment and the support frame. When approaching an obstacle, the elastic swing arms come into action. The segment deviates upwards. Immediately after passing the obstacle, the segment is returned by the prestressed swing arm back into the clearing position.

The snow ploughs of the Ramox range are renowned for their excellent reliability, first-class service and attractive price-performance ratio. The excellent equipment finish and the use of tried-and-tested components are further proof of the great technical expertise built into our machines.

The snow plough family Ramox is rather extensive standing out due to high quality and durability.

Key specifications

Available in various sizes

3 or 4-furrow swing-arm (high quietness and low noise)

Elastic connection between the segments

and the support frameUnique fixing of the plough shares in a defined clearing position

Special paintwork

Selection of different cutting edges

Key features

Swing-arm snow plough

High smoothness and low noise for professional snow removal in the city and community area.

Override safety system

The security system of the snow plough is based on the elastic connection between the segment and the support frame. When approaching an obstacle, the elastic swing-arms occurred in action. The segment deviates upwards. Immediately after passing the obstacle, the segment is returned by the biased swing arms back into the clearing position.

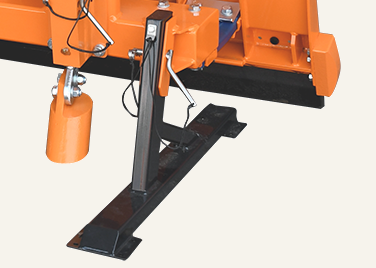

Wear-resistant skids

Take up part of the plough weight and are height adjustable and made of cast iron.

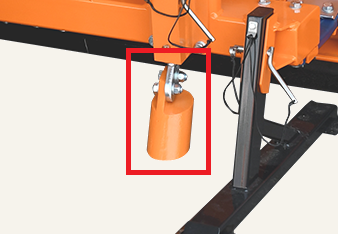

Parking system

For safe parking of the snow plough.

Side fenders

The side fenders prevent damage to the plough in lateral collisions.

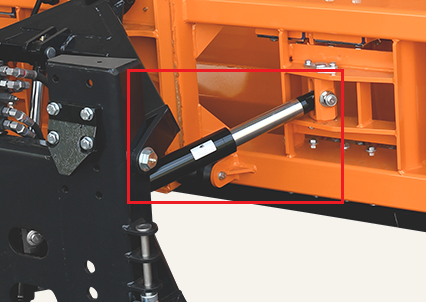

Hydraulic cylinders

The snow plough has a hydraulic side adjustment with two hydraulic cylinders.

Assembly plate

The Assembly plates (size F1 and F2) are manufactured according to DIN EN 15432 and must match with the mounting plate of the carrier vehicle. The adaptation is made by the height adjustment of the mounting claw.

LED side clearance lights (optional)

The LED side clearance lights are resistant to vibrations and external agents. They also ensure optimal visibility of the snow plough for all road users.

Flags (optional)

The flags ensure optimal visibility of the snow plough for all road users.

Warning mark (optional)

The warning mark on the share section additionally ensure optimal visibility of the snow plough for all road users.

Rubber splash guard (optional)

The rubber splash guard limits snow splashes on the vehicle windscreen.

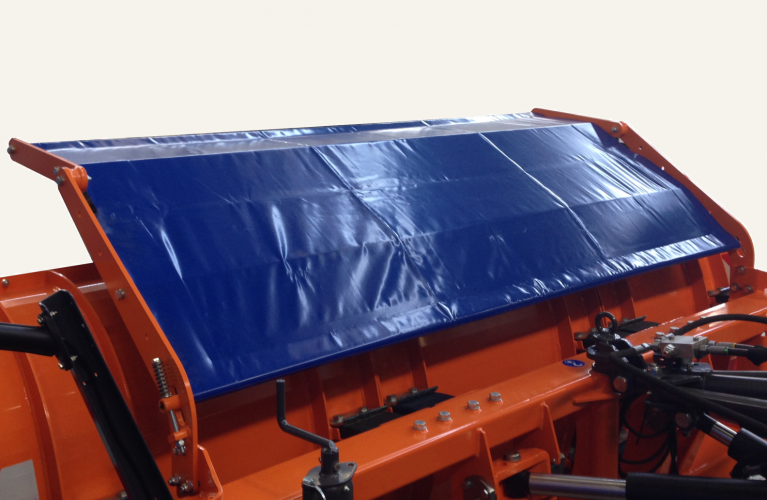

Adjustable snow screen (optional)

The adjustable snow screen guides the snow under the vehicle and thus provides a clear view of the driver.

Height-adjustable wheels (optional)

Suitable for high working speeds and reduce wear on neoprene and plastic scrapers.

Electric power pack (optional)

The electric power pack is available in a 12V or 24V system. It generates the required hydraulic power for the plough if no hydraulic supply is available from the carrier vehicle.

Cutting edge

- Snow clear bar in steel (a very hard, low-priced Snow clear bar)

- Snow clear bar in plastic (a quiet, surface-friendly Snow clear bar)

- Snow clear bar Kombi "S" (Combination bar from wear-resistant special steel, rubber and “Korund” for aggressive eviction)

- Snow clear bar GK5 (Highly abrasion-resistant and low-noise rubber clear bar)

Get to know more

The painting is done in the three-step painting process. In the pretreatment the plough gets degreased with hot water at a high pressure method (100 bar water pressure) and sanded afterwards. Subsequently, the primer is carried out in a high pressure spraying with an epoxy resin-base metal. After curing, the surface will be sanded again before the original painting gets applied in a high-pressure process. In the basic set-up is a high-solids polyurethane paint in the shade RAL 2011.

Other snowploughs

Discover Bucher Municipal

Find out why Bucher Municipal is the perfect partner for you.

Buy our products

and services

Providing products and services

around the world.