MaxPowa V65

Engineered to last, designed to perform

The V series has been developed from over 50 years of evolution and continuous improvement to meet customer requirements.

With tailored machines in your chosen field, we offer a wide choice of products and options, which ensure maximum performance is always achieved.

The MaxPowa V65 has been developed to provide longer on-station time with the lowest environmental impact, combined with ease of use and low operational costs.

Get to know the MaxPowa V65

Designed to last

The MaxPowa V65 sweeper operates at the lowest cost, with a large 190 litre auxiliary fuel tank giving increased on-station time. In addition, maintenance costs are significantly reduced on the gearbox and fluid coupling, as no belts or high wearing components are required. The Bucher MaxPowa V65 provides the lowest emissions and running costs. Suction sweeping requires fewer components, resulting in less wear and tear which in turn reduces maintenance costs.

Designed to suit operational requirements

The MaxPowa V65 is designed to fit a wide range of chassis models to suit specific operational requirements, the MaxPowa V65 sweeper will provide the power and performance to complete the task.

All V series sweepers benefit from Smoothflow technology. The re-designed airflow system maximises air delivery and minimises losses, improving suction performance whilst reducing fuel consumption and noise.

Maximising on-station time

Maximising on-station time requires a balance of having enough water capacity to minimize refills, having enough hopper capacity to cope with large volumes of leaves or debris, having a payload great enough to meet demands of a workday and being able to carry enough fuel to reduce non-productive travel.

The MaxPowa V65 provides the ideal balance between performance, environmental impact and low cost of ownership, with applications to suit a full range of sweeping environments, benefits that make the Bucher MaxPowa V65 the sweeper of choice worldwide.

Low Water usage

The V series uses as standard yellow mist atomizing jets to reduce water usage by 20%, or red nozzle jets with higher flow are available for heavier applications. The optional Water Recirculation system can save up to 900 litres of water per day extending the on-station time and reducing the risk of dust going through the fan.

Key specifications

6.5 m³ hopper capacity

1575 litre water tank

4mm 1.4003 Stainless steel hopper

Wireless discharge control

Trailing sweepgear

4* EUnited PM10/2.5 Certifed

Key Features

Designed to last in the toughest environments

The MaxPowa V65 hopper is manufactured from 1.4003 stainless steel, shot blasted with aluminium oxide prior to the application of a strontium based primer followed by a hard wearing top coat. In addition, all grey parts such as the sweepgear, powerpack and subframe are shot blasted and electro-magnetically powder painted in a durable two part epoxy paint finish. This ensures the sweeper continues to look as good as it performs, retaining a high residual value or longer in-service life.

Monitor sweeper performance

The CANbus system monitors sweeper performance and provides daily checks. The display incorporates as standard an audible and visual raised hopper warning, fuel gauge, engine hour metre, tachometer and a water level gauge. In addition data can be downloaded via a USB stick, showing a range of information from fuel consumption to average sweeping times.

A full CANbus integrated door mounted control pad allows the operator to safely adjust all the sweep options.

The new MaxPowa V65 is equipped with a radio controlled remote pendant allowing the operator to walk completely around the sweeper without having wires to contend with.

The operator can adjust the wide sweep brush easily to extend brush life and can check the surroundings before opening the hopper or tipping.

Designed with Safety in mind

The highly visible, self-engaging body prop provides the operator and service personnel with a safe working environment. The V series features a wireless radio controller allowing the operator to walk completely around the sweeper. The operator can adjust the wide sweep brush easily and check surrounds before opening the rear door or tipping.

High visibility brush plates and hose sleeves make it easier for the operator to see the brush position. The V series is also supplied with an LED sweepgear work light as standard and a wide range of additional LED and hazard warning lights are also available.

The auxiliary engine and hydrostatic drive pump is accessed via a wide lightweight service ladder giving three-point of contact, which can be folded away when not in use. All critical controls including valves, solenoids and auxiliary equipment for pneumatic, hydraulic and water systems are contained in a purpose built locker on the right hand side of the vehicle. The ease of access to this equipment facilitates diagnostic checks and maintenance.

Additionally, the MaxPowa V65 is also fitted with waterproof IP67 automotive electrical connectors for enhanced reliability. MaxPowa V65 models have equipment storage lockers on both sides of the hopper for storage of hydrant or wanderhose extension tubes.

Designed with the operator in mind

The MaxPowa V series has been brought right up to date with a large 10" touch screen. With clear updated graphics ease of operation is guaranteed. The in-cab centre console featuring cup holders and USB charging points can be adjusted to suit the operators preference.

The 10” colour JVM screen is mounted on an articulated arm allowing tilt angle and rotation to be adjusted without the need for any tools. The JVM has a wide range of settings that can be tailored to suit the operational needs for efficient sweeping performance. Provision has been made for up to six fully programmable buttons so the machine can activate your chosen sweep settings at the touch of a button.

The ergonomic door controller can be used for all sweeping operations, brush position, pressure, speed, nozzle aperture, engine revs and water jets. A heavy duty pause button allows the operator to lift all the sweepgear until depressed again. This allows the operator to change from sweeping to transit in a quick and easy way. Usability has been enhanced with a full LED halo surrounding each individual button which illuminates when active for ease of identification.

Water purging system as standard

Water purging system so that when freezing weather conditions are anticipated, water is easily and conveniently drained from the sweeper by a simple in-cab switch. Water jets in the nozzle boxes are self-cleaning which extends the life of the components.

Up to 2275 litres

The MaxPowa V65 has a 1575 litre stainless steel water tank integrated in the lower portion of the hopper and an optional 700 litre additional water tank is also available. The MaxPowa V65 uses yellow mist atomizing jets to reduce water usage by 20%, alternatively red nozzle jets with higher flow are available for heavier applications. For increased productivity, an optional water recirculation system can save up to 900 litres of water per day extending the on-station time and with the added advantage of reducing dust emissions.

Up to 3600mm with simultaneous sweep option

The MaxPowa V65 offers up to 3600mm swept width with the simultaneous sweep option (for dual sweep machines only), set almost flat makes short work of light application surface cleaning.

Product variations

MaxPowa V65t with twin

engine

Twin engine options offering performance and flexibility for truck mounted sweepers

Being independent of the truck chassis, the sweeper auxillary engine powers the sweeping functions and vacuum system so both engine and chassis can be tailored to the application and customer preferences. A wide range of chassis can also be supplied with either manual, automatic or automated gearboxes providing a wide range of options to suit the operator.

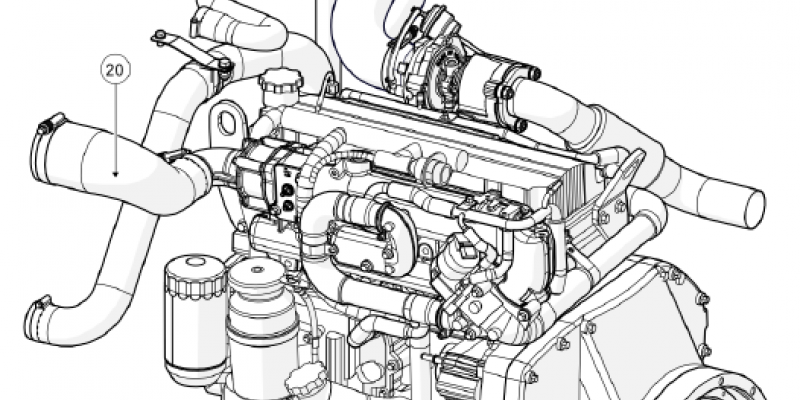

The MaxPowa V65t has a JCB 55 kW industrial engine designed for operating in dusty environment. Providing 440 Nm of torque at 1150 rpm the Stage 5 engine is ideally suited for road sweeping operations whilst offering low fuel consumption (EU27 only).

The option of a JCB 97 kW engine is also available offering a max torque of 550 Nm at 1500 rpm for applications where higher suction power is required; for example more arduous road construction operations (EU27 only).

Outside of the EU an optional JCB 85 kW Stage 3a can be offered with a max torque of 440 Nm at 1300 rpm.

Throttle control of the auxiliary engine is infinitely variable ensuring optimum operational and fuel efficiency with no performance compromised. With a 1500 rev Eco-mode built into the MaxPowa V65t, fuel conservation and noise levels are enhanced.

Once set to an operating performance, the twin engine sweeper system will perform at the same level regardless of gradient and travel speed. The sweeping operation can be paused or stopped easily and sweep gear lifted to allow the driver to transit from one location to another without having to disengage a separate drive.

MaxPowa V65h with hydrostatic

drive

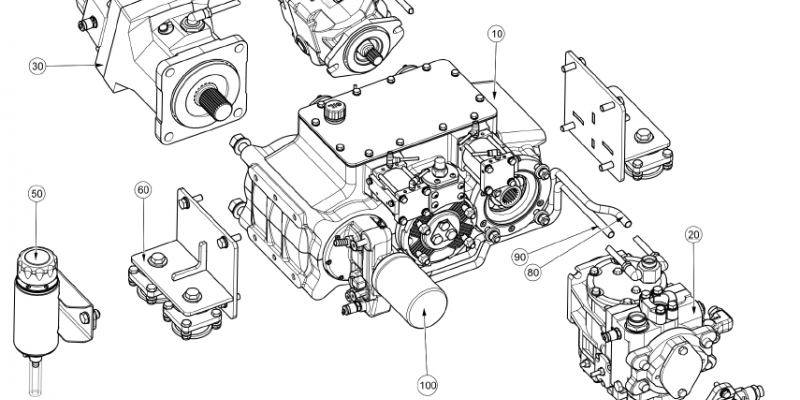

The patented HBG3 hydrostatic drive option is ieally matched for chassis up to 16 tonne GVM, perfect for built up areas such as towns and cities where sweeping speed and control are an advantage.

In hydrostatic drive, the sweeper offers infinitely variable speed control and can transit up to 40 km/h.

A transmission controller automates the power and torque supplied by the chassis, instantly matching the chassis rpm to the requirement of the operation. It can also be supplied with a cruise control option, so the operator can fix the hydrostatic mode speed of the sweeper on all gradients and applications, ideal where constant low speed operation is required.

MaxPowa V65m with chassis

PTO drive

The MaxPowa V65m is a single engine truck mounted machine and is offered alongside our existing truck mounted machines. All sweeping functions are driven directly by the chassis engine PTO rather than our auxiliary engine options of the MaxPowa V65t or the hydrostatic gearbox option of the MaxPowa V65h.

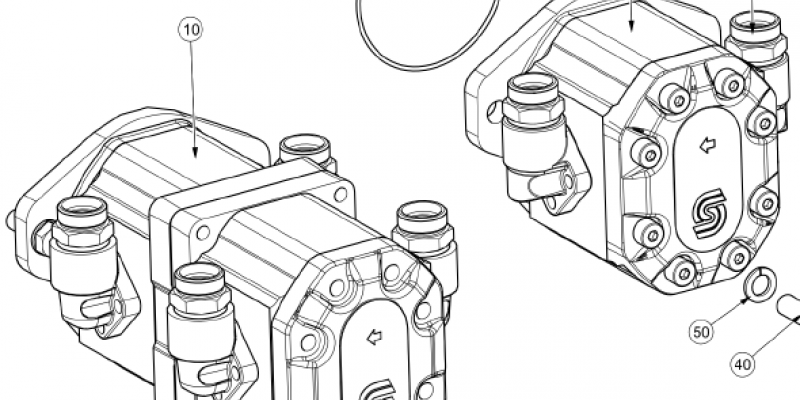

The MaxPowa V65m powapack is similar to the MaxPowa V65h using a 800 mm diameter hydraulically driven fan impellor, but in place of a hydrostatic gearbox has a large 130 cc hydraulic fan pump which is directly driven by a drive shaft from the chassis engine PTO.

The hydraulic fan pump in turn drives a gear pump which controls all sweeping equipment, and, in the event of supawash being selected then a tandem pump is fitted to run the additional hydraulic required.

The MaxPowa V65m has been designed to operate at maximum sweeper performance at just 1000 rpm of the chassis engine.

The chassis engine rpm may increased, either with the chassis cruise control (chassis dependant) or the foot pedal. This increases the forward speed of the vehicle but does not increase sweeper performance as it will have already attained maximum suction performance at 1000 rpm.

All this combines to keep fuel consumption, noise and forward speed to a minimum.

MaxPowa V65t with demount sweeper option

The MaxPowa V65t export skid unit is available as a demount sweeper option. This provides the ability to demount the sweeper body from the chassis to allow mounting of winter and other equipment making optimal use of the vehicle and allowing for a multi functional machine.

Other truck mounted sweepers

Discover Bucher Municipal

Find out why Bucher Municipal is the perfect partner for you.

Buy our products

and services

Providing products and services

around the world.