Briner liquid deicer

Reliability & Effectiveness: Bucher Briner sprayers for tough conditions

Designed for heavy trucks, our innovative technology provides reliable and precise spraying of liquid chlorides and solutions.

Designed for heavy trucks, the Bucher Briner sprayer is ideal in terms of performance, reliability and precision for spraying liquid chlorides and solutions thanks to innovative technology. Thanks to its experience, Bucher Municipal has developed this equipment with reference to all road, motorway and airport contexts.

Get to know the Briner liquid deicer

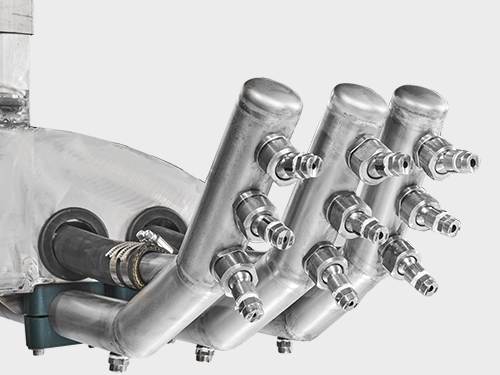

Bucher Briner is renowned for its innovative liquid deicer technology, which includes a unique "triangular" spraying technique using advanced nozzles. This cutting-edge solution guarantees total coverage of any surface, even in the most challenging conditions like snow-covered or icy roads. With Bucher Briner's expertise, you can rely on achieving the best possible coverage in any situation.

Through extensive research and unwavering dedication, we have successfully developed a state-of-the-art machine that guarantees reliability and delivers top-notch performance. This cutting-edge technology can effectively deal with snowy surfaces using a mechanical rather than chemical approach. The key to its success lies in the vertical spray of a specially formulated liquid de-icer solution, which is applied under high pressure.

The control panel receives signals from electronic sensors to indicate any malfunctions in the equipment or depletion of the material that needs to be spread. Additionally, safety and road traffic signs are available in different models with lights and protective features, in accordance with various safety requirements and regulations.

Key specifications

Application

Highways and Roads, AirportsPainting

tested for more than 2000 hours in salt fogNozzle bars and nozzles

3 nozzle bars each fitted with 9 nozzlesStandard spray width

11.5 - 23 - 34.4 ftSolution dosing capacity

186.4 ÷ 879.7 lb/lane/mileDrive

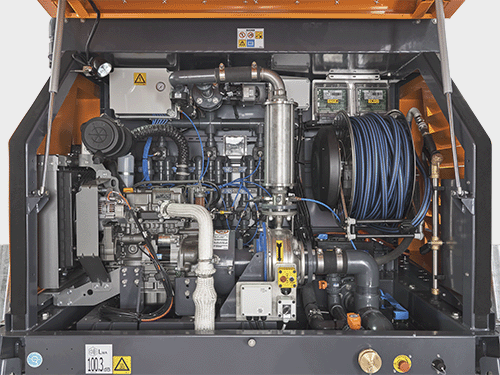

By the vehicle's hydraulic system or an auxiliary diesel engine

Key features

High-strength weather-protected rear technical compartment

Rear bonnet in high-strength steel to protect the technical compartment (pump, valves, electrical/electronic components and auxiliary engine, if present). The technical compartment is opened using gas-operated springs.

Unlocking efficiency and savings with our 17.9 in manhole covers

The 17.9 in diameter for inspections or maintenance ensures excellent performance and reduces the need for replacement and management overheads.

Experience the safety and reliability of our modular tank solutions

Modular tanks in recyclable polyethylene and connected to each other to create a solid structure that also retains flexibility such so that it can be mounted on the vehicle chassis without affecting its elasticity. The low centre of gravity and the flow breakers inside the individual tanks ensure safe driving in all load conditions, even on uneven paving.

Maximize efficiency and precision with nozzles

The brine is spread on the ground through 3 nozzle bars each fitted with 9 nozzles entirely in stainless steel controlled by pneumatic valves. Machine operations are managed automatically based on the parameters set on the control panel.

Achieve precision and power with front bar's swivelling spray technology

Swivelling front bar with spray width up to 7.9 ft and spray pressure up to 40 bar (alternative maximum pressure 120 bar). Drive is via the vehicle's hydraulic system.

Boost Productivity and Accuracy

Microprocessor tachometer control system with maximum programming flexibility and display of the various spreading parameters: width, asymmetry and dosage in relation to vehicle speed.

Discover Bucher Municipal

Find out why Bucher Municipal is the perfect partner for you.

Buy our products

and services

Providing products and services

around the world.