Mixspray

Limewash Mixer and Sprayer

Mix the solution on demand and directly on the vehicle.

The slaked lime sprayer MIXSPRAY MS10 has been designed to mix and spray on demand the calcium hydroxide during asphalt laying operations. The slaked lime is increasingly being used in asphalt laying on tack coat to avoid the tack coat-tire adhesion thanks to its anti-adhesive properties.

It is used to prevent that tack coat is torn off by tires of vehicles operating in the construction site, with a considerable saving of materials, increasing efficiency and reducing cleaning costs of the roads in the neighborhoods, decreasing the environmental impact on construction sites, particularly in urban areas.

Get to know the Bucher Mixspray

Thanks to the welded steel chassis the equipment can be easily mounted on different kind of trucks guaranteeing the correct elasticity and a comfortable and safe driving. Hook-lift frames are also available.

Polyethylene tanks With 2500l capacity each, are provided of visual level indicator and electrical minimum level indicator. The equipment, thanks to its shape, has a low gravity centre and the driving is safe thanks to the tanks geometry and to inside breakwaters.

The parameters that can be set from the control box are:

- Dosage Solution quantity per m²

- Concentration Quantity of calcium hydroxide per unit of water

- Spraying width of the treated road surface.

- Speed related spraying the solution dosage is always constant independently from the vehicle speed.

The MIXSPRAY has an automatic washing system to remove the lime particles from all the mechanical parts (pumps, valves, nozzles..); the automatic washing can be activated once the work is finished.

During the washing cycle, pressured water is pushed into pipes and all mechanical parts that were in contact with lime.

Thanks to the automatic wash all the equipment maintenance costs are reduced and its working life increases.

Key specifications

Max dosage 300 g/m2

Limewash Solution1000 l

Water 4x2500 l

Mix 5 -20 %

Spreading width 3,5 - 5 m

Key Features

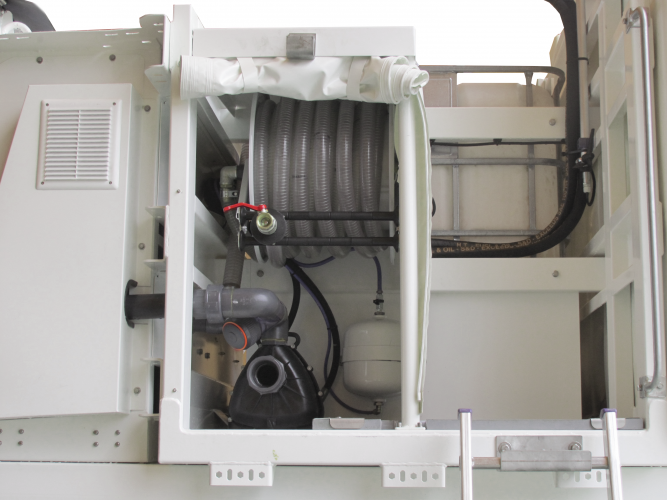

Hose reel and pump

Hose reel and pump to fill the tanks. The hose reel allows to fill tanks with non-pressured water; it has a maximum flow rate of 200l/min.

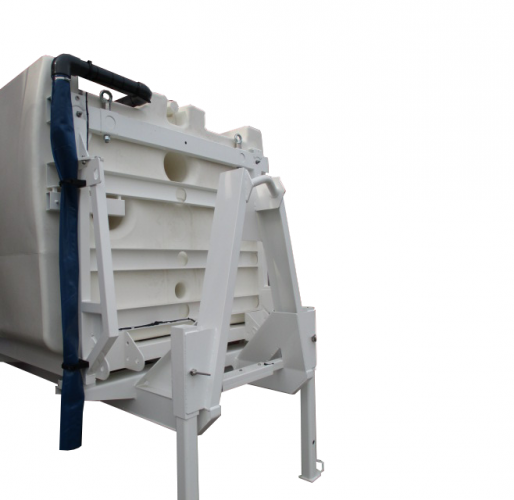

Welded steel chassis

Thanks to the welded steel chassis the equipment can be easily mounted on different kind of trucks guaranteeing the correct elasticity and a comfortable and safe driving. Hook-lift frames are also available.

Polyethylene tanks

With 2500l capacity, eachare provided of visual level indicator and electrical minimum level indicator. The equipment, thanks to its shape, has a low gravity center and the driving is safe thanks to the geometry and to inside breakwaters.

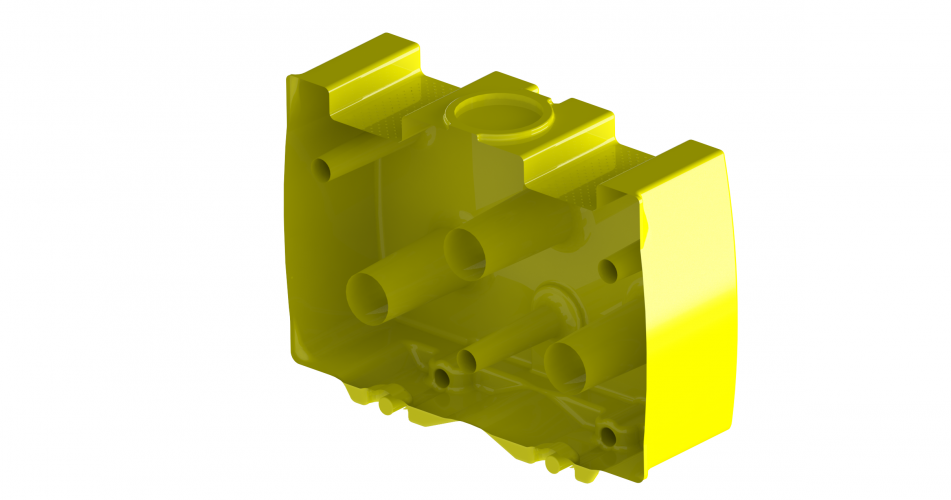

Technical compartment

All the valves, pumps, filters, electrics “and electronics” components are in the rear technical compartment to better protect them and to make maintenance operations easier.

The 3 nozzle bars

Allow a homogeneous slaked lime solution application and asphalt humidification.

The direction of all the 5 nozzles, presents in each bar, is adjustable. This system has easy maintenance in case of failure.

Ecos

It is a microprocessor control box having a maximum flexibility in spreading setting.

Based on CAN BUS technology.Four different spreading and asymmetry programs can be set.

Ladder

Easy access to all technical compartments, hose reel, and hydraulic connections thanks to rear and lateral ladders.

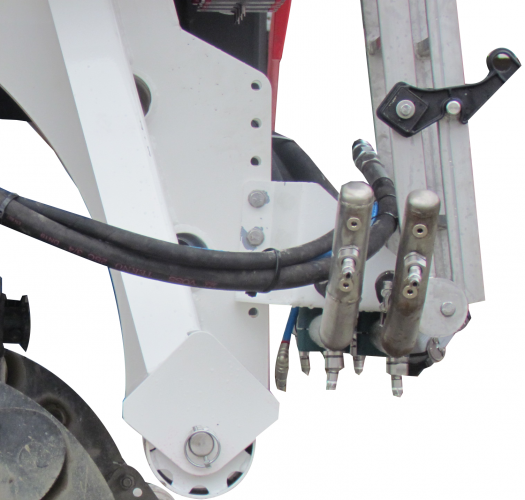

Hydraulic System

The driving system works through the truck hydraulic system. The interface connections between vehicle and equipment are complying with the European Standards EN15431.

Discover Bucher Municipal

Find out why Bucher Municipal is the perfect partner for you.

Buy our products

and services

Providing products and services

around the world.