UniQa salt spreader

Versatile solution for medium & heavy trucks. Precise spreading on all roads.

Upgrade your truck's capabilities today with UniQa Spreader. Experience unrivaled efficiency and precision in road maintenance!

UniQa is a spreader for medium or heavy trucks which can be used with salt, sand or gravel. The hopper, fully welded to prevent vibrations, is made from thick high strength steel (STAINLESS STEEL on request) to allow a large loading capacity without deformation.

Ideal for all types of roads, motorways, car parks and public areas. It has a chain extraction system with parallel crossbars made of high strength steel. Due to its large extraction width, the hopper bottom is wider with more vertical walls to prevent any type of bridge effect even with difficult materials at low temperatures. The feedback sensor automatically adjusts the chain speed to guarantee constant feeding and uniform discharging of the material from the hopper with excellent spreading precision without the typical pulsating flow of an auger. The roller breaker placed crosswise at the bottom of the chain conveyor system provides a constant, uniform flow of material to the spreading disc and breaks all the lumps conveyed by the conveying system into small parts.

Get to know the UniQa spreader

The high number of combinations of solid and liquid capacity allows the machine to adapt to any type of heavy truck (not forgetting the correct solid/liquid ratio and a balanced load distribution on the axles). UniQa is perfect for winter road maintenance, de-icing or anti-icing applications: it can be configured to spread different types of material, salt, sand or grit, depending on the needs.

The guidance system can be customized to meet the requirements of a dedicated winter truck or a standard transport truck. The smart control system can be implemented over time with automated features that offer step-by-step upgrades and high resale value

A large use of stainless steel and durable polyethylene components ensure high protection degree over it entire lifespan while reducing maintenance costs.To further extend the corrosion protection all steel and stainless steel assembly are shoot blasted and powder-coated with a specific double layer treatment or galvanized.

To facilitate the maintenance process, we also offer a centralized greasing system that allows all stainless steel bearings to be reached from an easily accessible greasing point. Wherever possible, consumable parts are designed to minimize maintenance costs by not replacing the entire assembly but only the part subject to wear.

We believe in a sustainable growth of our generation permitting the future generation to fulfil its needs without restriction.In fact more than 90% of UniQa weight can be recycled and some of its components are made of recycled materials too.

The most accurate spreading pattern available on the market combined with the highly automated functions optimize the spreading material application reducing costs and environment pollution.

Also in our production factory we care about the environment: the production location are ISO 14001 certified and in our paint shop we are using from many years the powder recuperation system which ensure the primer is recycled and reused reducing waste of resources. Also the energy supply consumption source from our photovoltaic system and a certified supplier of renewable energy because we believe in a cleaner world.

Key specifications

Application

Urban areas, Airports, Highways and Roads, Mountain roadsPainting

tested for more than 2000 hours in salt fogCapacity of hopper

4-11 m3Min/max spreading width

2-12 mSalt dispensing capacity

0-40 g/m2Control panel

Ecosat

Key Features

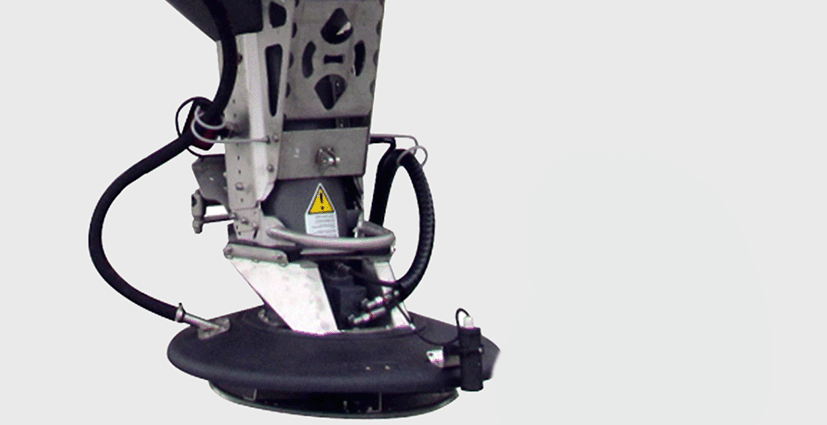

Precision spreading unit: adjustable asymmetry. Optimize material distribution!

Spreading unit with 600 mm diameter disc with all metal parts made of AISI 304 stainless steel and adjustable asymmetry. Open unit for excellent spreading of all materials. The chute leading to the spreading disc is made of HD polyethylene with a circular cross-section, cast moulded to allow the salt to flow at low temperatures. The spreading disc has 6 blades. The blades have variable geometry to adjust the spreading of the material to the particle size. Can be used with a wetting system with a nozzle above the spreading disc.

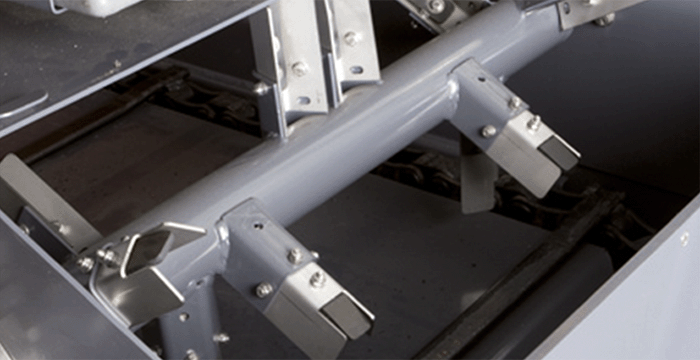

Drive efficiency and reliability with our cutting-edge steel belt solutions

The system consists of a wide metal belt made of steel with high strength cross bars. The metal belt is driven by pinions which maintain constant traction and correct timing without sliding.

Smooth and continuous material spreading with roller breaker - No more lumps!

This allows material to flow continuously from the hopper to the spreading unit, breaking down any lumps and preventing them from dropping in an uncontrolled way.

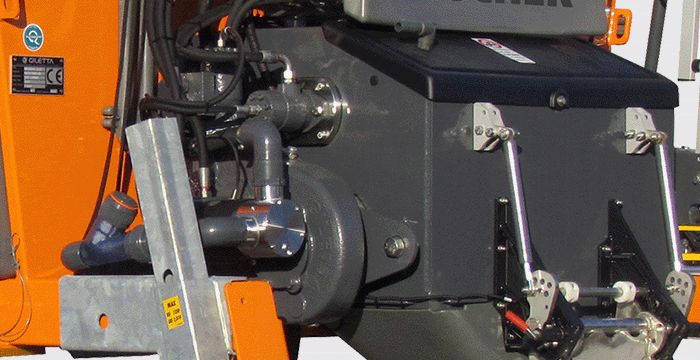

Advanced Wetting System: Low Maintenance, Precise Control.

The wetting device has a Bucher volumetric pump directly flanged to the hydraulic motor which is maintenance free. The nitrile rotor only requires internal washing at the end of the season. The solid/liquid ratio is electronically controlled from the control panel in the driver’s cab.

Robust side tanks: eco-friendly polyethylene. Compatible with MBS snow plow

The side tanks are made of recyclable, sturdy, light-weight rotomoulded polyethylene with a sight gauge and breather cap. It can be used together with the snowplough MBS system.

Secure compartment: polyethylene construction, easy electrical connections.

Protective compartment for black box and valve block. Made of polyethylene and containing a rack for the electrical connections.

Bucher ASSIST

An increasingly efficient fleet! Make your spreader smart and control spreading remotely with Bucher Assist.

Find out more DiscoverOther spreaders

Discover Bucher Municipal

Find out why Bucher Municipal is the perfect partner for you.

Buy our products

and services

Providing products and services

around the world.